來源:中為 瀏覽次數:次

Characteristics of aluminum anti-static floor adopts the high pressure die casting process, aluminum ingots melted, the high pressure die casting machine disposable vacuum die casting forming, fusion of aluminum alloy is resistant to corrosion, high strength, the floor surface can be according to the need for epoxy powder coating or nickel chromium plating to achieve the surface soft, corrosion, wear effect.

Function characteristic:

1, anti-static flooring series products in the best substrate, the best conductor, can be in the shortest time to the floor surface generated by the static electricity generated by the ground system.

2, surface abrasion, no bubble, no, light weight, performance is not attenuated.

3, four weeks to support, one structure, strong bearing pressure, more than 1.5 tons per square metre.

4, high-grade environmental protection, the product can be recycled and reused, not devaluation.

5, the structure of the novel, high dimensional accuracy, not easy to deformation;

6, quality light, high density, high strength, high carrying capacity;

7, waterproof, fireproof, anticorrosive, antimagnetic, environmental protection, no pollution, no radiation;

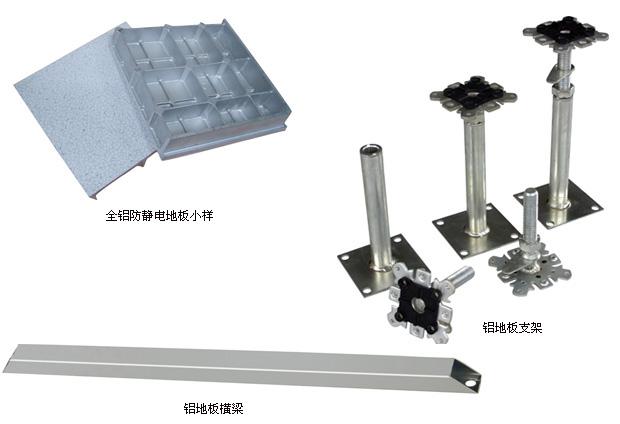

Product structure:

Product selection of aluminum as a substrate, using a large oil pressure machine die casting or casting molding. On the surface of the HPL or PVC with a strong adhesive tape, the support and the cross beam are chosen as the steel mould, and the wire rod can be adjusted freely.

Product application:

Banks, military, government and enterprises and institutions of high - grade room, clean room, clean room and the bearing and material requirements of high places.

Model technology and parameters:

|

International Model |

Specifications(mm) |

Fire performance |

Concentrated load |

Impact load |

limit load |

Uniform load |

Rolling load(N) | |||

| LB | N | KG | (N) | (N) | (N/m2) | 10times |

100000 times |

|||

| ZW800 | 600x600x40 | A | ≥800 | ≥3350 | ≥363 | ≥536 | ≥11250 | ≥16100 | 3560 | 2670 |

| ZW1000 | 600x600x40 | A | ≥1000 | ≥4550 | ≥450 | ≥670 | ≥13350 | ≥23000 | 4450 | 3560 |

| ZW1250 | 600x600x50 | A | ≥1250 | ≥5560 | ≥567 | ≥780 | ≥16680 | ≥33000 | 5560 | 4450 |

| ZW1500 | 600x600x50 | A | ≥1500 | ≥6675 | ≥670 | ≥1005 | ≥19892 | ≥34500 | 6675 | 5340 |

| ZW2000 | 600x600x50 | A | ≥2000 | ≥8900 | ≥906 | ≥1340 | ≥26700 | ≥46000 | 8900 | 8000 |