來源:中為 瀏覽次數(shù):次

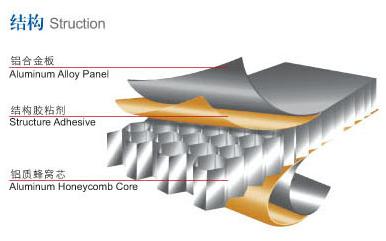

Aluminum honeycomb series is a "honeycomb sandwich" structure with the surface sprayed with weather resistance of the decorative coating of high strength aluminum alloy as a panel, the floor and the honeycomb core by high temperature and high pressure composite board. The series products have excellent colorful, advanced technology and reasonable structure, light weight, easy assembly and disassembly, wind resistance, compressive strength, sound insulation, heat insulation, insulation and strong, advantages. The scale and smoothness are excellent. Widely used in building interior and exterior curtain wall. Material: aluminum honeycomb board face, back plate are used in high strength aluminum alloy. Selected core material thickness 0.06mm, length 6mm, hexagonal honeycomb aluminum foil made of imitation. With double component polyurethane adhesive, high temperature and high pressure. Regular panel thickness of 0.8mm, 1.0mm, in the overall thickness of 10mm, 15mm or 25mm. Other specifications, structure and size according to the needs of the design and manufacturing, to meet the needs of a variety of purposes. Surface treatment: can be carried out on the plate surface fluorocarbon paint, polyester paint, imitation wood grain or electrostatic powder coating. The surface, color, specifications can be formulated according to engineering design. A kind of high quality, high strength, light green decorative materials. The appearance is luxurious and rich. Aluminum honeycomb board with anti-static, good steel, high flatness, sound insulation, the appearance of flat, color natural bright, elegant and bright, elegant and bright, easy to install, fast, can withstand high wind pressure, easy to clean, green, green and other characteristics, is widely used in modern architectural decoration.

Aluminium honeycomb board product raw material

Aluminum panels: the main selection of high quality 3003H24 alloy aluminum or 5052AH14 high alloy aluminum plate as the substrate, the panel for the 0.7~1.5mm of the fluorocarbon roller coating.

Aluminum plate: the bottom thickness is 0.5-l.Omm

Aluminum honeycomb core material: using hexagonal 3003H18 type aluminum honeycomb core, aluminum foil thickness 0.04-0.07mm, length 5-6mm.

Adhesive: the two-component polymer film and two-component epoxy modified epoxy resin.

The surface of the curtain wall aluminum honeycomb panel is coated with the coating. The surface of the aluminum sheet can be effectively controlled by the coating. The surface of the aluminum sheet can be controlled effectively. The particle size of the traditional spraying process can be eliminated successfully. Containing not less than fluorocarbon resin or Hylar5OOO 70%Kynar500 fluorocarbon polymer coating is the main component of the, is a most stable molecular structure durability combined with paint, fluorocarbon coatings painting product can long against the sun's ultraviolet radiation, industrial waste gas, acid rain and chemical erosion, long-term to maintain the stability of the color is bright and clean, coating peeling, cracking, powdering.